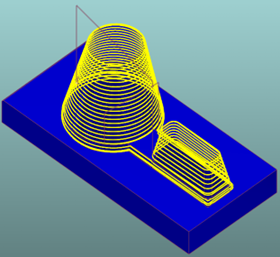

Spiral

| The Spiral Finishing Cycle, allows you to perform a finish with a constant pitch with a Helix descent over the entire part without rising, the different areas of the part are detected and managed automatically and the first and last passes of each area are constant. |

Key Points

Application:

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath Strategy | ||

Reworking | Slopes Reworking | Stepover (Tool ratio) |

Stepover value (Ae) | Flat face rework | |

Limitation of Machining | Limitation Area | |

Calculation of Z Steps | Z Step (Ap) | Constant Scallop |

Scallop value | ||

Allowances | XY Stock allowance | Z Stock allowance |

Normal stock allowance | ||

List of altitudes | List of altitudes | |

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | Rapid plane alt. | Safety distance |

Approach and return in Z | Retract altitude | |

Safety (in XY) | SD/ Tool shank | Management of toolholder |

Leadin and leadout in XY | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Spindle speed | Feedrate | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |

| |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | Gouge Check | Offset XY |

Safety area | Offset Z | |

Curves Computing | Curve tolerance | Curve segmentation |