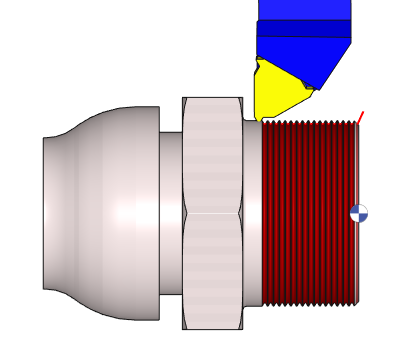

Threading - Turning

| This threading operation generates a cylindrical or a conical threading while the profile threading can can follow an evolutive profile. |

Key Points

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

Back turning | ||

Pitch and Passes | One page gives the explanation for those parameters: click here Calculate pass, Machining Depth, Pitch 1st pass depth, Nb of threads, Last pass depth Stop before extra passes, Nb of passes, Nb extra passes | |

Machining Strategy | XY Stock allowance | |

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Spindle speed |

Cutting speed | Feedrate in Z | |

Speed range | Spindle direction | |

Feedrate | Maxi spindle speed | |

Tool Numbering | Tool number | Specific Number |

Length compens. nb | Radius compensation number | |

User information | Comment | Control Device |

Machining Set |  | |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety Area | ||