Preparation for Machining

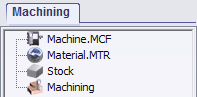

This step enables to prepare the machining environment, before starting to program the toolpaths. We can consider 4 main actions:

Stock Creation

Load Machine File

Load Material File

Manage Origins and Settings

Stock Creation

Maybe the stock was already imported or created during automatic solid import; if not, once we go from Design to Machining menu, we get into the definition of the stock shape. Click here for more details: Creation of Stock.

Machine File

A machine-tool in the machine shop is a NC controller combined to a machine with specific mechanical characteristics and mounted tools. This is exactly what is defined in the machine file. In most cases, the machine file is not obligatory to generate the iso program, but it is greatly advised to define it. Click here for more details: Machine File |  |

You can define a default machine file in Tools / Options / Machining. This machine is automatically loaded each time you open GO2cam.

Material File

Choosing a material file means loading cutting conditions tables associated to your tools.

You can use default material files or create and save your own tables in a specific editor.

These 2 stages are available through the machining tree, complementary commands are available with a right-click.

Click here for more details: Material File

Manage Origins and Settings

By default, the Program Origin is the origin of the REFERENCE plane.

If you want to define the origins differently, two cases are explained here: Manage Origins and Settings

1- How to change the PO (Program Origin)?

2- How to declare G54/G55/Gxx planes for operations?

In this page, we also describe how to program a flip-flap on a workpiece.