Origins

Presentation

|  | This page describes how to define and how to assign origins to the workpiece. You can also declare specific syntax to origins. |

1. Program Origin

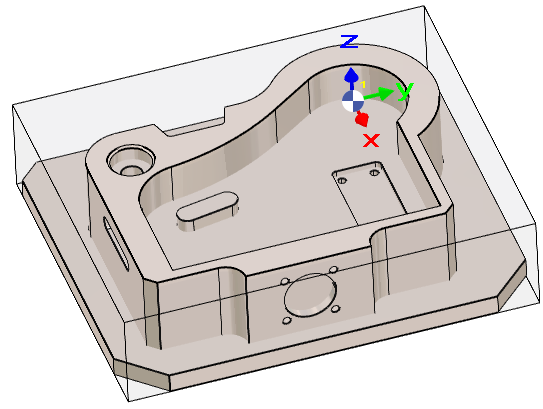

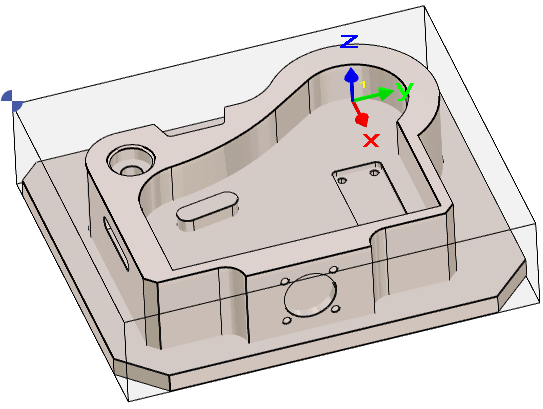

By default, the Program Origin is the origin of the REFERENCE plane. When you go to the Milling menu, the Program Origin is displayed in the screen with a symbol. But you may want to modify the origin for the whole operations. Do not use Move commands for this! In the Machining Tree, in line Stock, click Single Origin and click the new point. A Machine file must be loaded to be able to accede to the change of origin. This is because the settings of the origins is done in the Machine file. |  |

|

In WIre EDM, you can also use the Single origin command.

It will create a new origin but still keep the Z0, only X and Y positions will be modified!

2. Multiple Origins

| The mechanism to define origins is homogenized with the MTE module. It is especially useful when you need several origins in your project. The process is the following:

| |

To access the command, in the machining tree, right-click on Stock and choose Machining origins. | ||

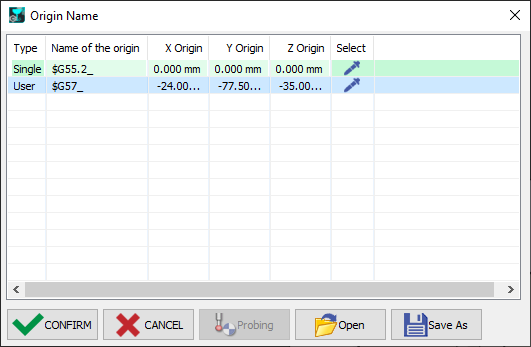

In the pop-up table, right click on a blank cell then choose Add an origin or Add a single Origin.

| ||

Use the selection Pipette on the row and choose a point on the solid to define the origin. Using the same principle, you can define multiple origins on the part and double-click on the origin name to rename it. The configuration can be saved for future use and click on Confirm to validate the origins. | ||

3. Assignment of Origins

Once the origins are created in the table of origins, you have to assign the origins to the operations. There are 2 methods, depending on your configuration with or without MTE.

Process without MTE

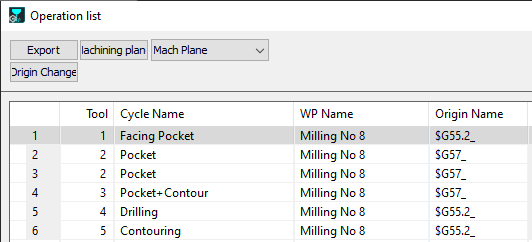

You need to open the Machining List, then choose Machining Planes (Mach Plane in the combo list). Select the row of the cycle requiring origin change then click on the Origin Change button to access a drop-down list of all the origins defined. Choose the adequate origin for the cycles and simply close the window. The button Origin Change does not exist if you have the MTE module! Please read below. |

Process with MTE

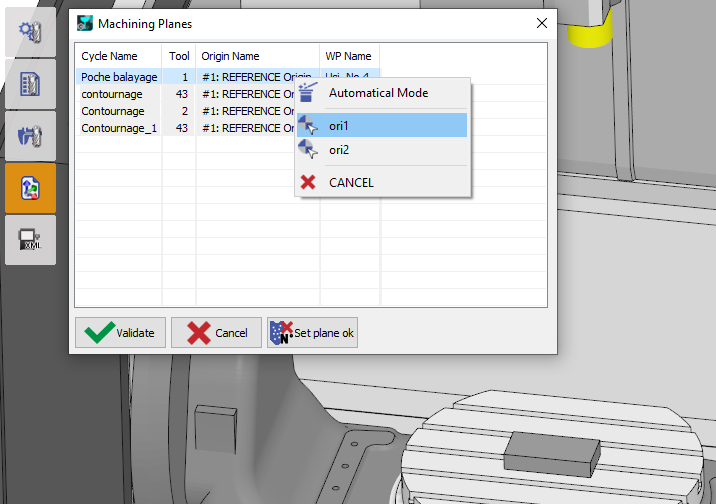

The assignment is done in the Tooling menu, in the command Machining Planes'. Do a right-click in the line of operation and select the needed origin. |  |

In the simulation, the specific origin for each cycle will be displayed on the screen, and also the labels of the origin will be visible in the coordinates dialog with coordinates taking into consideration the position of the current origin.

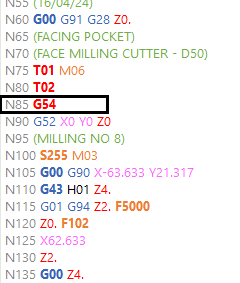

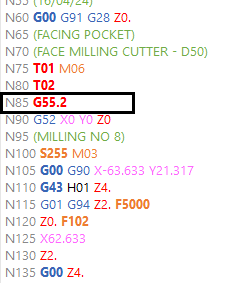

The NC file will be calculated according to the defined origins.