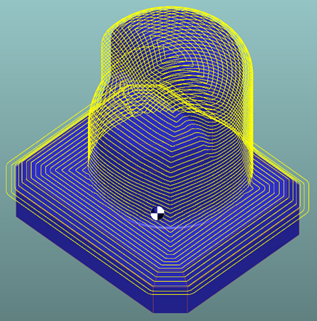

Equidistant

| Equidistant finishing is intended for machining relatively regular shaped parts. The machining is determined by a reference curve which can be the machining area. The path is parallel to the reference curve. |

Key Points

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath Strategy | Inversion of path | |

Drive Profile and Limitation of Machining | Offset on drive profile | Calculate drive profile |

Offset on limitation profile | Contouring on limitation profile | |

Stepover Calculation | Stepover (Tool ratio) | Stepover value (Ae) |

XY Scallop | ||

Allowances | XY Stock allowance | Z Stock allowance |

Normal stock allowance | ||

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | Rapid plane alt. | Safety distance |

Approach and return in Z | Retract altitude | |

Safety (in XY) | SD/ Tool shank | Management of toolholder |

Leadin and leadout in XY | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Spindle speed | Feedrate | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | Gouge Check | Offset XY |

Safety area | Offset Z | |

Curves Computing | Curve tolerance | Curve segmentation |