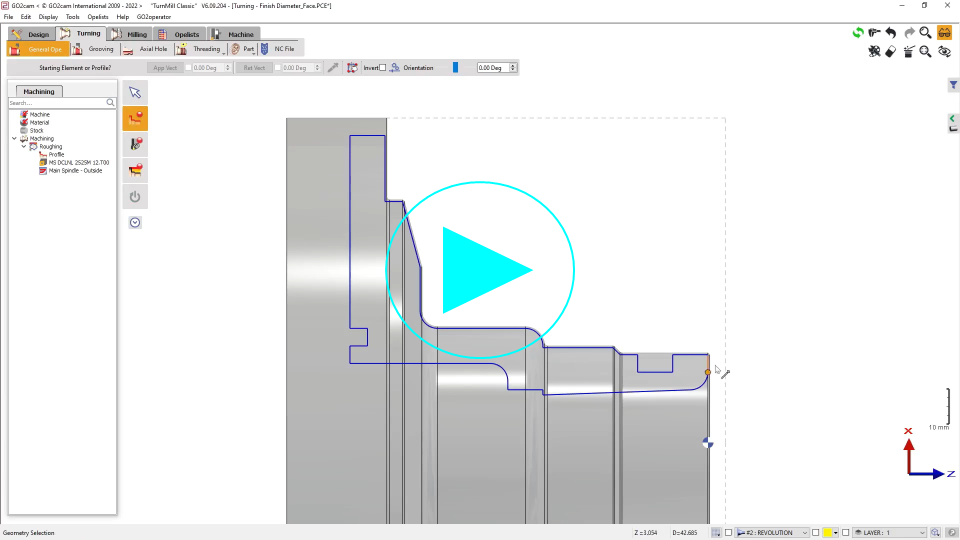

Finishing Diameter and Face

| Finishing pass with different options for toolpath, by mixing diameters and lengths with different priorities. |

Key Points

|

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | Type of cycle | |

Finishing Strategy | ||

Machining Strategy | Local stock allowance | |

XY Stock allowance | ||

Z Stock allowance | ||

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | ||

Overlength on face | Overlength on diameter | |

Safety distance | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Maxi spindle speed | ||

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

User information | Comment | Control Device |

Machining Set |

| |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety area | ||

Curves Computing | Curve Tolerance | Curve explode into |

Options | ||

Options on the toolpath | Break the outside corners | Maxi angle |