Set

| The "Set" function help to approach and managing complex NC programs. It allows you to group operations together based on users needs criteria, making your program more organized and easier to edit. |

Accessing the "Set":

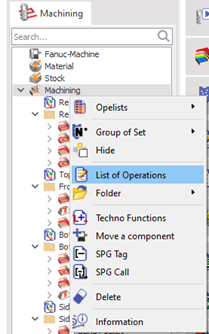

Double-clicking the Machining icon opens the List of Operations window. |  | |

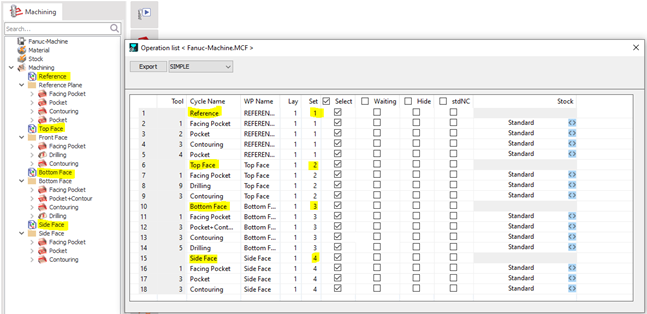

Grouping Operations with "Set":In the List of operations, the "Set" column allows you to assign numbers to group related operations. For example, you can group operations by:

|  This example demonstrates grouping operations based on their associated part settings | |

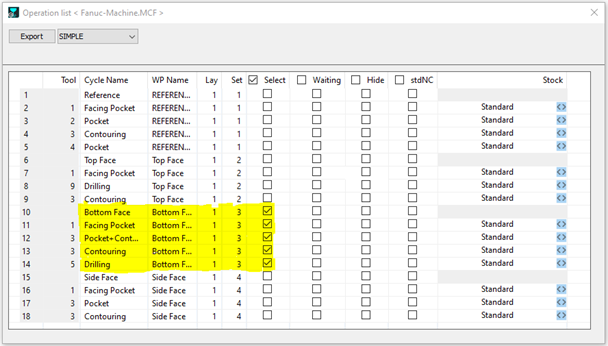

Controlling Output with "Set":

|  In this example only the Bottom Face has been selected. | |

Generating the NC Program:

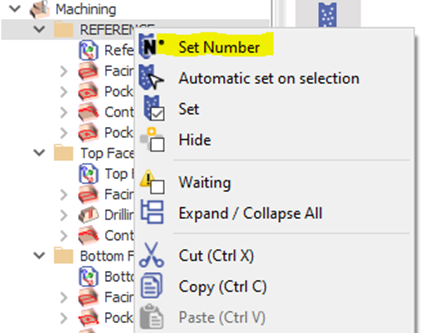

In this example ‘Automatic Set on Selection’ can be use to output the Bottom Face operations. Simply right-click on the desired operations and choose "Automatic Set on Selection" from the menu.

|  | |

Tips:

|  | |

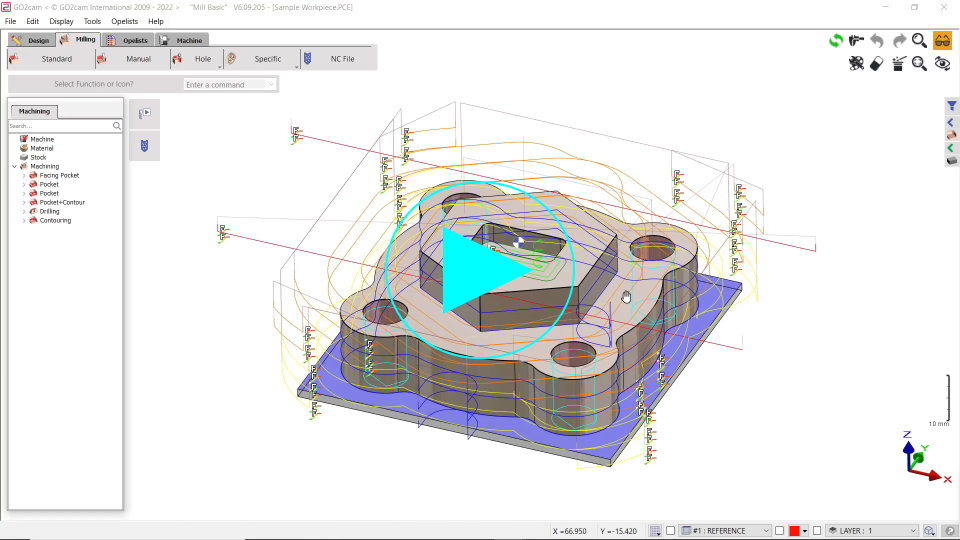

▶️ This video walks you through using the 'Set' function to generate NC programs by tool being used. | ▶️ This video demonstrates defining part settings and using 'Set' to generate NC programs for specific Part settings. | |

|  | |

SET Group

What are SET Groups?

A way to organize and quickly select machining operations for simulation and generating NC program code (ISO blocks).

Aims to make using the "machining set" filter more efficient, compared to the less suitable "batch" state.

|  | |

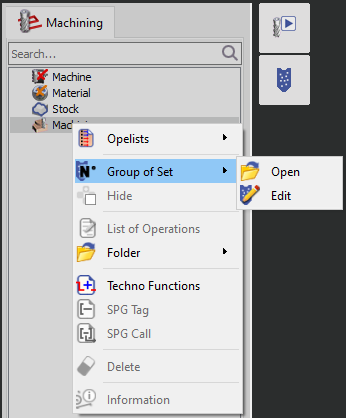

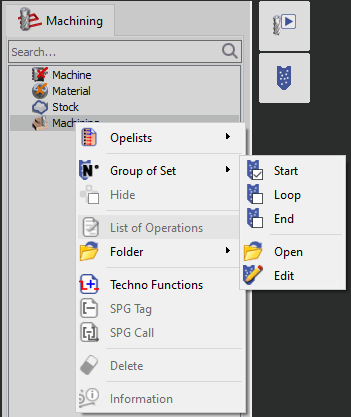

How to Use Set Groups:

| ||

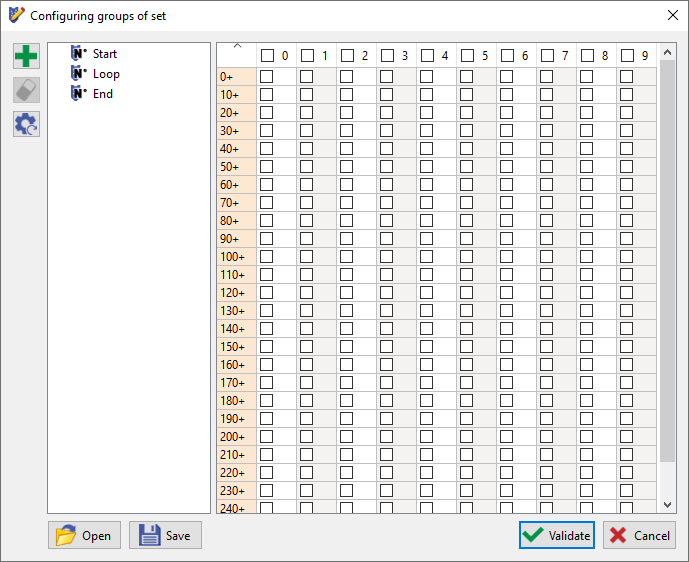

Creating SET Groups:

|  | |

Example: Two-Spindle Machine: Imagine a machine with two spindles. You want to create different programs for various production stages:

SET Groups allow you to define sets for each program (start, loop, end cycles). By activating or deactivating specific sets, you can generate and simulate the three separate programs needed for this scenario. | ||