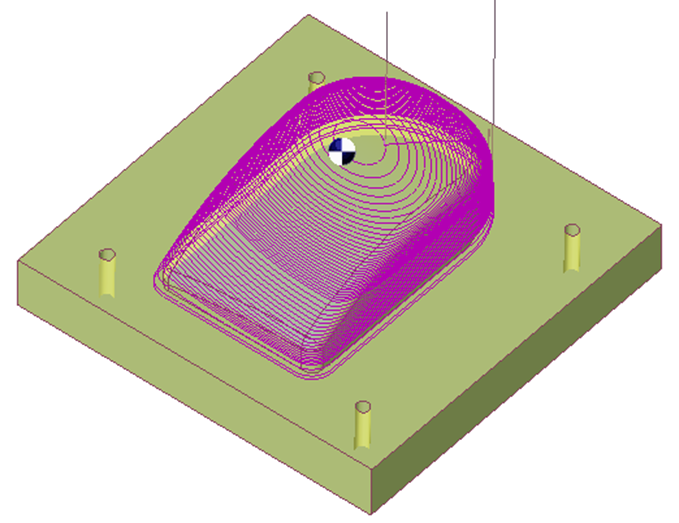

Z Level

| Z Level finishing is intended for machining parts containing vertical or nearly vertical walls in contouring. Machining begins with the highest point of the part. The cutter follows the contours of the model remaining at a constant level. |

Key Points

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath Strategy | ||

Undercut machining | Radii on contour | |

Reworking | Slopes Reworking | Stepover (Tool ratio) |

Stepover value (Ae) | Flat face rework | |

Limitation of Machining | Limitation Area | |

Calculation of Z Steps | Z Step (Ap) | Constant Scallop |

Scallop value | ||

Allowances | XY Stock allowance | Z Stock allowance |

Normal stock allowance | ||

List of altitudes | List of altitudes | |

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | Rapid plane alt. | Safety distance |

Approach and return in Z | Retract altitude | |

Type of leadin in Material | Leadin forced in XY | Leadin following a slope |

Angle of the slope | ||

Safety (in XY) | SD/ Tool shank | Management of toolholder |

Leadin and leadout in XY | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Spindle speed | Feedrate | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | Gouge Check | Offset XY |

Safety area | Offset Z | |

Curves Computing | Curve tolerance | Curve segmentation |

Toolpath Computing | Decomposition of arcs of toolpath | Arcs decomposition tolerance |