Optimum Setting

Presentation

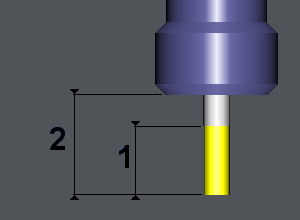

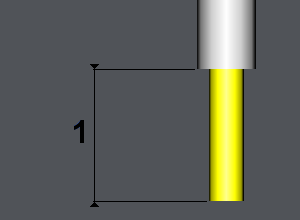

| Automatic optimization of the cutting length and the useful length of the tool according to the solid part size. |

This function is running only if there is a solid part.

▶️ You can watch a video at the bottom of page: Click here |

Reminders and Use Constraints

Reminders:

|  |  |

Constraints: the function is running if:

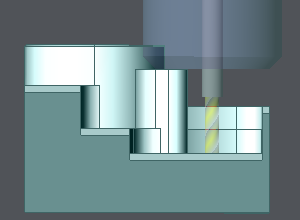

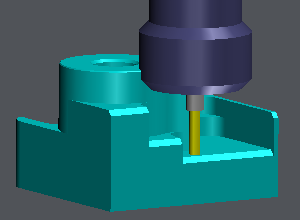

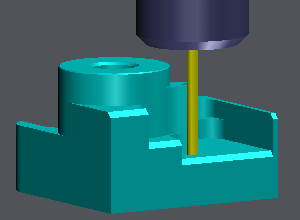

This example on the right shows the machining of the pocket. The tool cutting length is not enough to machine all the pocket. The useful length is not enough neither, there are collisions between the holder and the part. |  |  |

To activate the Optimum Setting function

In the machining Tree, do a right-click on the chosen cycle. Choose Toolpath Techno, then Optimum Setting.

The following dialog zone appears:

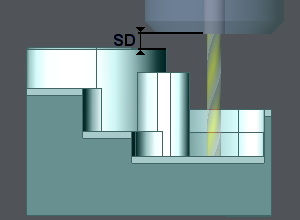

On the left is the name of the tool used in the cycle, given as an information

Safety Distance: value to add to the part size. You can enter any value.

Useful length:

the first field is the current value taken from the tool page. It is given as an information.

the second value is calculated by GO2cam: part size + safety distance.

RED CROSS : to cancel the function

GREEN TICK : to validate and apply the value calculated by GO2cam.

When you validate the Optimum Tool function, the value calculated is automatically applied in the tool page. You can simulate and see the modification immediately. | |

|  |