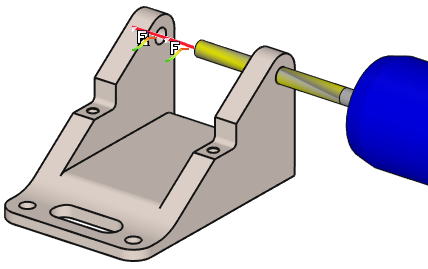

Clevis

| Clevis mode enables to accelerate motions between 2 or more axial holes. |

Key Points

This mode aims to accelerate the feedrate between 2 or more axial holes. Mandatory rules to program a clevis operation:

Click here for more detailed explanation: Clevis |  |

Strategy Parameters

Dialog Area | Parameters | |

Depth | Depth | |

Retract | ||

Final dwell | ||

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | ||

Approach and return in Z | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Level | Spindle speed | |

Feedrate | Rapid feed | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | ||

Safety area | ||