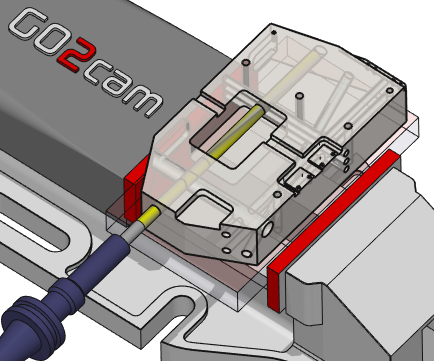

Gundrilling

| Deep drilling, also called gundrilling is a specific process to drill deep holes |

Key Points for Deep Drill

Special options are applied, such as the management of feed and spindle speed at the start and end of machining and when intersecting other holes or cavities. Mandatory rules to program a deep drilling operation:

Click here for more detailed explanation: Deep drilling |  |

Strategy Parameters

Dialog Area | Parameters | |

Depth | Depth | |

Retract | ||

Leadin Strategy | ||

Stop for leadin control | Spindle for entry | |

Feedrate for entry | ||

Leadout Strategy | Retract Distance(Peck) | |

Spindle for retract | Feedrate for retract | |

Final dwell | ||

Speeds | Reduced feedrate | |

Feedrate in cavity | ||

Intersections | ||

Cavities | Distance after entering cavity | Mini size of cavity |

Distance before leaving cavity | ||

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | ||

Approach and return in Z | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Level | Spindle speed | |

Feedrate | Rapid feed | |

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | ||

Safety area | ||