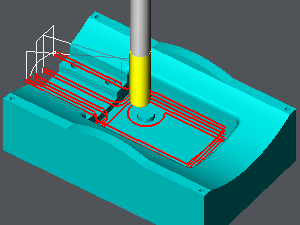

Finish Contour - Shape

| GO2cam applies automatically a 2D contouring on a 3D shape by Z increments, managing leadin and leadout motions and the tool radius compensation. |

Key Points

Main parameters are very close to the 2D cycles parameters.

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath and Compensation | Toolpath | |

R max coef | Rework machining | |

Limitation of Machining | Limitation Area | |

Calculation of Z Steps | Z Step (Ap) | |

Stock Calculation | ||

Allowances | ||

List of altitudes | List of altitudes | |

Movement Parameters

Dialog Area | Parameters | |

Safety | ||

Approach and return in Z | ||

Safety (in XY) | XY safety distance | |

Management of rapids | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Level | Spindle speed | |

Feedrate | ||

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | ||

Safety area | ||

Curves Computing | Curve segmentation | |

Toolpath Computing | Decomposition of arcs of toolpath | Arcs decomposition tolerance |