TurnyuGO

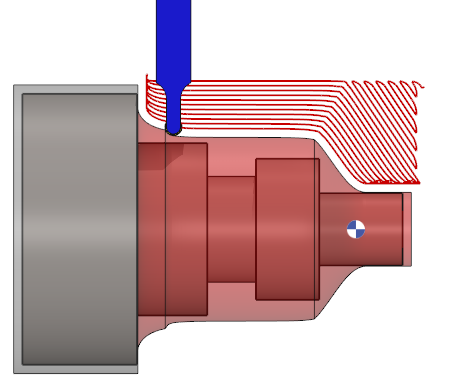

| As the similar milling operation ‘millyuGO’, turnyuGO is a roughing operation with a constant load of tool and regular chips. This operation can be programmed only with button tools. |

Key Points

This cycle, based on the millyuGO technology, enables to calculate toolpaths with a constant load on the tool. Main benefits:

Only button tools can be used for this machining operation. TurnyuGO includes G2/G3 to reduce the iso program. The program length is divided by 10. You can also reduce the length by changing the curve tolerance. |  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

Machining Strategy | Radius on contour | Diameter of loops |

Pass Depth | ||

Z Stock allowance | XY Stock allowance | |

Chip breaking | ||

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Pass feedrate | Maxi spindle speed | |

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

Users Fields | Comment | Control Device |

Machining Set |

| |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety area | ||

Safety distance in Z for rapids | Safety distance in X for rapids | |

Curves Computing | Curve Tolerance | Curve explode into |

Options | ||