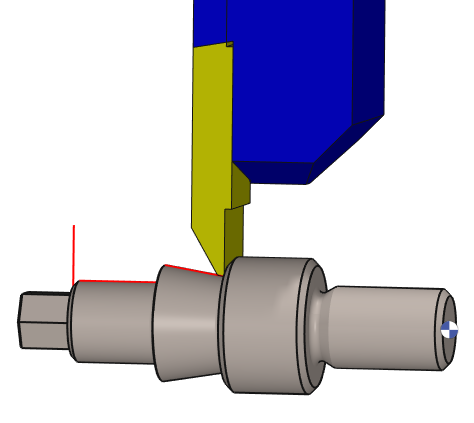

Form Finishing

| Finishing operation is done with forming tools, especially for Back turning operation. |

Key Points

The tool can either be a turning facing cutter or a forming tool. By using the forming tool, there are low radial forces, better chip- control as well as better result. The cutting edge changes throughout the machining. Tools files formats *.sym and *.ouf can be used. Libraries of ISCAR and Kyocera tools are available in downloading. |  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

Machining Strategy | Step along profile | |

Local stock allowance | ||

XY Stock allowance | Z Stock allowance | |

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | ||

Leadout overlength/Vector | ||

Leadin overlength/Vector | ||

Limitate the leadin/leadout | ||

Return safety distance | Approach safety distance | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Maxi spindle speed | ||

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

Users Fields | Comment | Control Device |

Machining Set |  | |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety area | ||

Curves Computing | Curve Tolerance | Curve explode into |

Options on the toolpath | Break the outside corners | Maxi angle |