Balanced Roughing

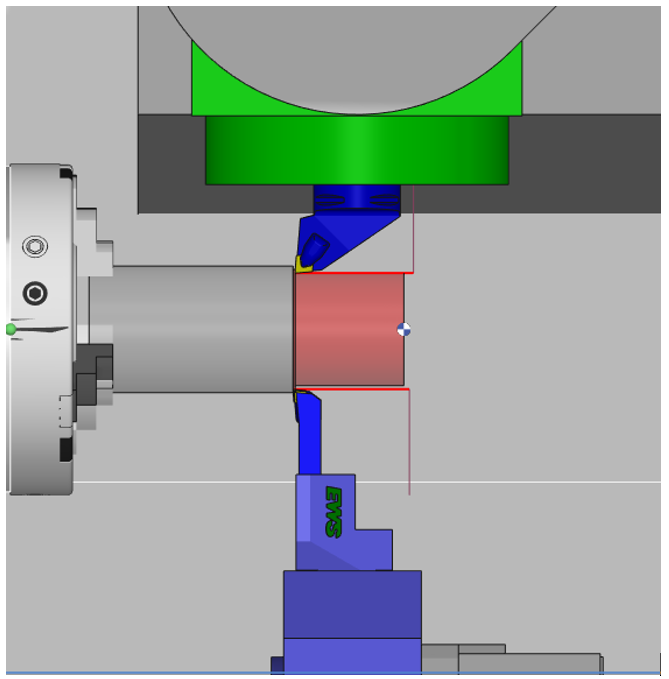

| Roughing operation programmed with 2 tools mounted on 2 turrets (or spindle) and synchronized by different possible modes. The toolpaths can be outside, inside or facing. |

This machining cycle is available only with the optional module MTE.

Key Points

For turning machines with dual turrets, mill-turn machines as well as Swiss machines, balanced operations unlocks new possibilities by allowing users to program simultaneous turning operations using tools on the opposite sides.

|  |

The standard simulations (Dynamic and Toolpath) will not show the reality of the cutting, the synchronizations and a possible different second tool. You should always simulate balanced operations with MTE control simulation.

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

R max Coef | ||

Synchronization | ||

Machining Strategy | Passes | |

Retract | Pass Depth | |

Last Pass Depth | ||

Angle of passes | ||

Local stock allowance | XY Stock allowance | |

Deburring | Z Stock allowance | |

Chip breaking | ||

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | ||

Over cutting | Undercut safety distance | |

Facing | Linitate on Z axis | Exceed the the axis |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Pass feedrate | Maxi spindle speed | |

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

Opposed Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

Users Fields | Comment | Control Device |

Machining Set |

| |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety area | ||

Curves Computing | Curve Tolerance | Curve explode into |

Options | ||

Compensation achievement factor | Coeff of feedrate reduction | |