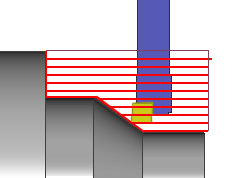

Roughing

| This cycle is a multi-use operation; it manages outside straight toolpath, but also facing, inside reaming and even back facing machining. The passes stay parallell to the axis while the cycle Parallel roughing generates a toolpath parallel to the selected profile. |

Key Points

This cycle offers many technical options:

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

R max Coef | ||

Machining Strategy | Passes | |

Pass Depth | ||

Last Pass Depth | ||

Angle of passes | ||

Local stock allowance | Z Stock allowance | |

XY Stock allowance | Deburring | |

Chip breaking | ||

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | ||

Over cutting | Undercut safety distance | |

Facing | Limitate on Z axis | Exceed the axis |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Pass feedrate | Maxi spindle speed | |

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb | |

Users Fields | Comment | Control Device |

Machining Set |  | |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety area | ||

Curves Computing | Curve Tolerance | Curve explode into |

Options | ||

Compensation achievement factor | Coeff of feedrate reduction | |