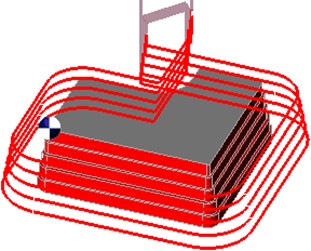

Taper Cutting

| This cycle is special, you need first to define the taper with the specific command in design menu. |

Key Points

You can program tapers in contouring toolpath with compensation (G41/G42). For this, you must create the taper in geometry with the command Taper Creation. You can define constant or evolutive tapers. |  | |

| Taper Creation is located in Design>Taper submenu. Click here for more information! | |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath and Compensation | ||

Toolpath Strategy | 2 Ways Path | |

Calculation of Z steps | Z Step (Ap) | |

Allowances | ||

Overcutting | Manage open areas | |

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | ||

Approach and return in Z | ||

Motions between Z approach and XY leadin | ||

Leadin and Leadout in XY | ||

Angle/distance calculation+tool radius | Radius calculation+tool radius | |

Z plunge distance on bottom radius | ||

Technology Parameters

Dialog Area | Parameters | |

utting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Level | Spindle speed | |

Feedrate | ||

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | ||

Safety area | ||

Curves Computing | Curve segmentation | |