Roughing Reworking

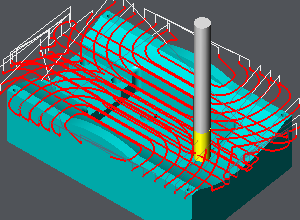

| The roughing consists in getting off the maximum of material to be the closest possible to the final shape before finishing stage. GO2cam applies automatically on a solid a pocket cycle with Z successive increments and remaining material management. |

Key Points

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath Strategy | ||

Limitation of Machining | Limitation Area | |

Undercut and Reworking | Undercut machining | |

Scallop value | ||

Stock Computing | ||

Stepover Computing | ||

Respect of scallop | ||

Z Step | Z Step (Ap) | |

Allowances | ||

List of altitudes | ||

Movement Parameters

Dialog Area | Parameters | |

Safety | ||

Approach and return in Z | ||

Z Plunge | ||

Management of rapids | ||

Safety (in XY) | XY safety distance | SD/ Tool shank |

Management of toolholder | ||

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Level | Spindle speed | |

Feedrate | ||

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |

| |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | ||

Safety area | ||

Toolpath Optimization | Rework Area Tolerance | |

Curves Computing | Curve segmentation | |

Toolpath Computing | Decomposition of arcs of toolpath | Arcs decomposition tolerance |

Cooling | ||