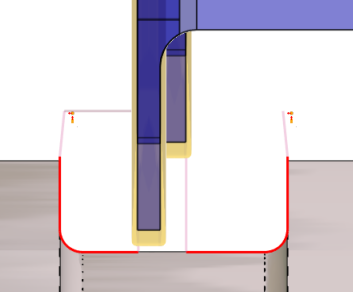

Finish Groove

| This finish cycle is supposed to be used after other grooving cycles. But it has also specific use:

|

Key Points

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath | ||

Offset type | ||

Machining Strategy | Local stock allowance | |

XY Stock allowance | ||

Z Stock allowance | ||

Movement Parameters

Dialog Area | Parameters | |

Approach and Return Characteristics | ||

Calcuation with tool radius | Leadin/Leadout | |

Technology Parameters

Dialog Area | Parameters | |

Cutting Conditions | Quality | Cutting Speed |

Spindle speed | Speed range | |

Feedrate in Z | Feedrate | |

Feedrate in X | Spindle direction | |

Maxi spindle speed | ||

Tool Numbering | Tool number | Specific Number |

Radius compensation number | Length compens. nb 1 | |

Length compens. nb 2 | ||

Users Fields | Comment | Control Device |

Machining Set |  | |

Options Parameters

Dialog Area | Parameters | |

Management of collisions | ||

Safety Area | ||

Curves Computing | Curve Tolerance | Curve explode into |

Options | ||