Chamfering

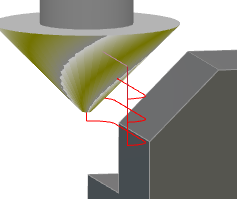

| Machining of chamfers whatever is the geometry. You can select the edges of the chamfer or program a chamfer on a sharp angle. |

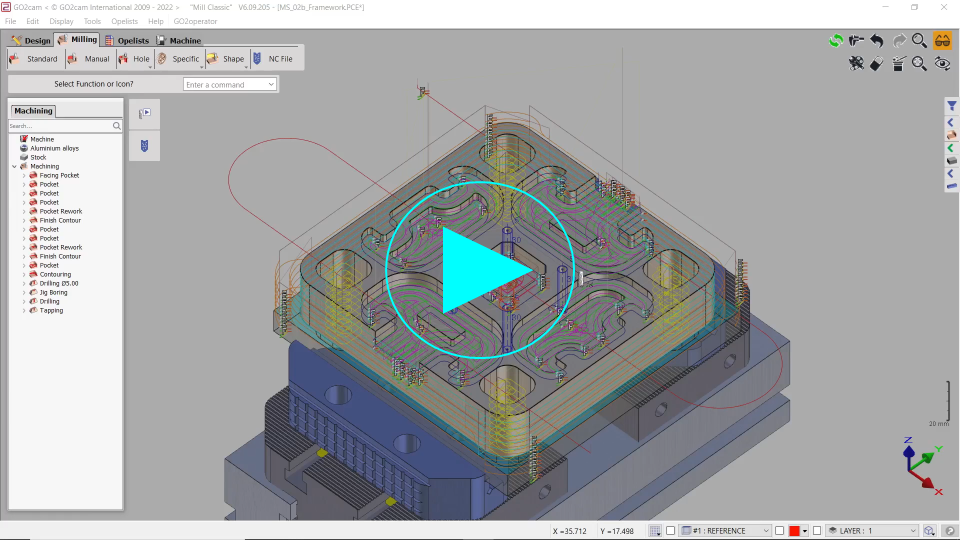

▶️ You can watch a video at the bottom of page: Click here |

Key Points

|  |

Strategy Parameters

Dialog Area | Parameters | |

Toolpath and Compensation | ||

Depth Recalculation | Delta | |

Chamfering Strategy | ||

Calculation of Z steps | Z Step (Ap) | |

Allowances | ||

Overcutting | Manage open areas | |

Double Chamfering Tool | ||

Movement Parameters

Dialog Area | Parameters | |

Safety (in Z) | ||

Approach and return in Z | ||

Motions between Z approach and XY leadin | Macro | |

Leadin and Leadout in XY | ||

Angle/distance calculation+tool radius | Radius calculation+tool radius | |

Z plunge distance on bottom radius | ||

Technology Parameters

Dialog Area | Parameters | |

utting Conditions | Quality | Cutting Speed |

Feedrate/tooth | Spindle direction | |

Level | Spindle speed | |

Feedrate | ||

Sp. speed range | ||

Tool Numbering | Tool number | Specific Number |

Length compensation number | Diameter compens. Nb | |

Users Fields | Comment | Control Device |

Milling Set |  | |

Options Parameters

Dialog Area | Parameters | |

Behaviour on the clamps and components | ||

Safety area | ||

Curves Computing | Curve segmentation | |

Toolpath options | ||

Maxi Angle | ||