Revisions - Improvements for GO2cam V6.11

Revisions are GO2cam versions mainly dedicated to fix software issues. Revisions are identified by numbers 201, 202, etc. and they are released approximatively once a month.

Minor improvements are sometimes added, they are described in this document. For the whole list of corrections, click here.

V6.11.211 | Improvements | 18th of March, 2025 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| Shaft Creation |  | Dimensions | When the drawing start is not X0Z0 but X20Z0 for instance, we display a dimension 0 for the Z distance. This dimension was very high in the screen, now it is displayed just below the Z axis. |

V6.11.210 | Improvements | 21st of January, 2025 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| Holes |  | Solid Subtraction | In Standard Holes and Users Holes Dialogs, we can now select the solid to substract in a combo list. |

V6.11.208 | Improvements | 05th of November, 2024 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| Workplanes |  | Workplane Origin | If a point was used as origin for 2 different workplanes, the 2 origins had the same name, which was not convenient. From 6.11.208, the origins will have different names even if they are one only geometric point. |

| Graphic User Interface |  | Group & Ungroup | Group and Ungroup commands are added in Edit menus of all the products and environments. |

V6.11.207 | Improvements | 01st of October, 2024 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| Wire-Cut EDM |  | To delete or to select a threading point, we can now click the circle itself, not only the center as previously. It makes the selection much easier! | |

| CAD Import |  | STEP import | The Step Import has been improved and is faster if file doesn't contain PMI. If file contains PMI, you can uncheck PMI option to import quicker. |

| 4 & 5 axis Simultaneous |  | We added safety distances before plunges, to avoid fake detection of collision during simulation. | |

| Machine Tool Environment (MTE) |  | Change of behaviour: in cycles with a 'set' to OFF, tools will not be tested anymore and consequently there will be no more error message and the simulation will be allowed to run. | |

V6.11.206 | Improvements | 03 of September, 2024 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| API |  | If a function is missing, we display the file name and the line where the error occurs. | |

| Turning |  | In the menu Shaft > Creation, we added the commands rectangle, ellipse, oblong and polygon. | |

| Wire-Cut EDM |  | It is now possible to create a threading point at the intersection of unlimited geometry. | |

| Tooling |  | In GO2Tools, we added tools for download for Vertical Turning:

| |

| Machining Generalities |  | In the case of trouble with the stock, we can now systematically edit it to be able to recreate it properly. | |

| Machining Generalities |  | In Turning, it is now possible to create a manual stock based on a geometric profile that includes curves. | |

| 4 & 5 axis Simultaneous |  | Computing has been improved to have better machining results. | |

V6.11.205 | Improvements | 02 of July, 2024 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| Holes Machining Features |  | Graphic User Interface | In the machining tree, we now display the name of the hole model. If several models are calculated at the same time, we use a generic name (Multi cycles). |

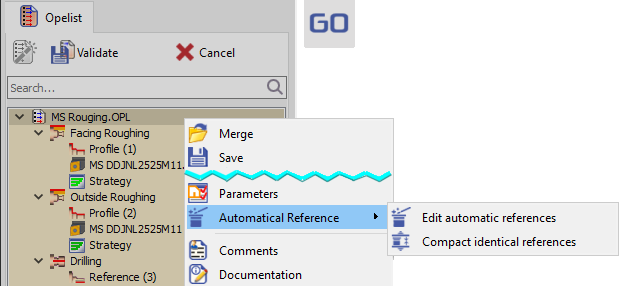

| Opelists |  | Automatic Opelists | We added a new option in the automatic references to compact and minimize identical references.  |

| Machining Generalities |  | Toolpath Techno Function | We made easier the selection of toolpath techno function |

V6.11.204 | Improvements | 28 of May, 2024 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| Graphic User Interface |  | We modified the behaviour of 'Backup Files', that are created when saving the .PCE file: the backup file was the file right after the save; now, the backup file is the last version of file before the save. | |

| CAD Import |  | Update of some CAD interface formats:

| |

| API |  | Add new functionnalities to create fillets or chamfers on solid (see GO2SSolid.ApplyFillet, GO2SFace, GO2SEdge) | |

| Wire EDM Geometry |  | We changed the display tolerance of threading point, so that display is now correct for very small diameters | |

| Machining Generalities |  | Edit Stock: we now allow margin modification when stock was created without history | |

| 5 Axis Expert |  | Update | We implemented the latest version of ModuleWorks. |

V6.11.203 | Improvements | 23 of April, 2024 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| Geometry |  | 2 new features:

| |

| Workplanes |  | New command to create customized workplane according to the position of the current view. | |

| User Interface |  | New behaviour when we create a new plane:

Consequently, the new behaviour is that a plane created always becomes the current plane and by default we do not change the view! If you want to change the view, set on the option. | |

| User Interface |  | The options set in this command are now saved and kept between 2 user sessions. | |

| API |  | We split "Combox_CurrentChanged" into two call back functions "ComboBox_CurrentIndexChanged" and "ComboBox_CurrentTextChanged" to be able to manage two different events. | |

| API |  | When adding a Javascript script in a user menu or toolbar, the icon can be customized by adding an image (png format) with the same script name in the script folder. | |

| API |  | When writing code, there is now an auto completion functionnality to help finding functions. | |

| API |  | New possibility to give arguments to Javascript scripts when launched by GO2cam in command line. Please read: http://support.go2cam.net:82/API_Help/GO2JScript/page_launch.html#autotoc_md50 | |

| API |  | New GO2SIniFile object to manage ini files in Javascript | |

| Machining Features |  | Slots | We added a parameter on slot features to know if they are open. $BGMF_OPEN_POCKET, 0 means close slot, 1 means slot open on one side, 2 means slot open on both sides. |

| Machining Generalities |  | User Interface | When there are features on the part, they are automatically hidden while selecting other machining cycles. |

| Machining Generalities |  | While editing the stock, margins are editable only if the option 'keep link with geometry' is activated: we added information in the dialog to explain it. This behaviour will be improved in V6.11.204. | |

|  | Vocabulary | New field in General vocabulary>Machining. Spindle enables to show if operations are done on Main or Sub Spindle. | |

|  | User Interface | To avoid too much screen contrast, the documents templates are now displayed in a grey colour when the background is black or very dark. | |

V6.11.202 | Improvements | 27 of March, 2024 |

Topic | Type | Subject | Explanation | |

|---|---|---|---|---|

| Graphic User Interface |  | New general behaviour of the software regarding views:

| |

| Layout Design / Dimensioning |  | Dimensions: when using inch unit, we added an option to have decimal instead of fractionnal display. | |

| Machining Generalities |  | In Milling, Cylindric stock can be tube shapes, thanks to the possibility of defining a inner diameter value. | |

| Simulation |  | When we go out from the simulation, we keep the view and zoom level that we have defined during simulation. | |

| Simulation |  | 4 Axis Roughing | By default, the simulation of the 2 new cycles of 4 axis simultaneous roughing are simulated with the part fixed and the tool turning around. For more realistic (but longer calculation), you can set off the options ‘Simplified Machining’ in the options dialog. |

| 2 Axis Milling |  | New behaviour of the option Z repeat, that enables to repeat exactly the same toolpath from a Z step to the next one and use subprograms. To be available, the toolpath must be:

| |

| 2 Axis Milling |  | Pocket cycles | Improvement of pocketing cycles that optimizes tool retracts in some cases. |