what-s-new-in-go2cam

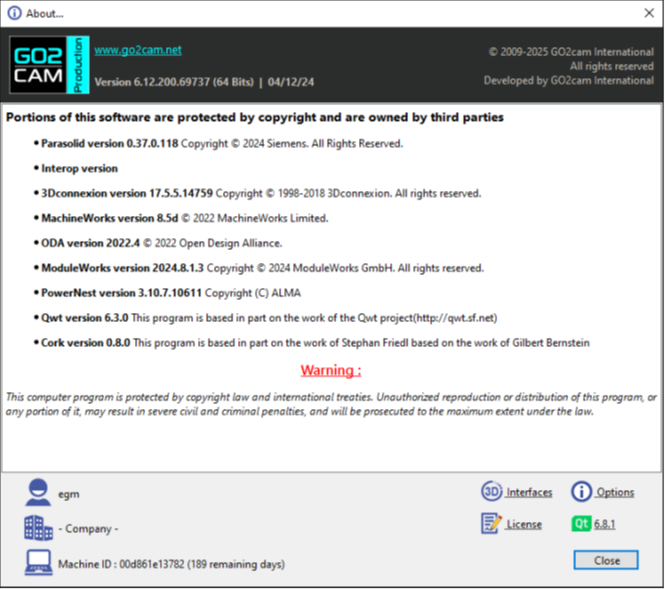

| List of new features and Improvements of GO2cam V6.12.201, released on 3 March 2025. Improvements added all along version’s life: Improvements of Revisions |

Icons used in the tables below |  | New Features |  | Improvements |

| Web and Services | |

|

| |

| Installation, System & Hardware | ||

|

The software installs to C:\Program Files\GO2cam_Intl\GO2camV612 by default, with the option to change this during setup. If an older V6.12 version exists, the installer suggests its directory for updating.

Special Case: Software Configuration (Options) is still saved in folder ini. One consequence to this new structure is to be able to work with GO2cam in multiple sessions in a safe way! | ||

| The User directory can be cleaned with a new utility: DelUserConfig.exe. This specific executable file that can be ran out of GO2cam, in case of trouble. It is available in GO2cam directory and with Windows Search. | ||

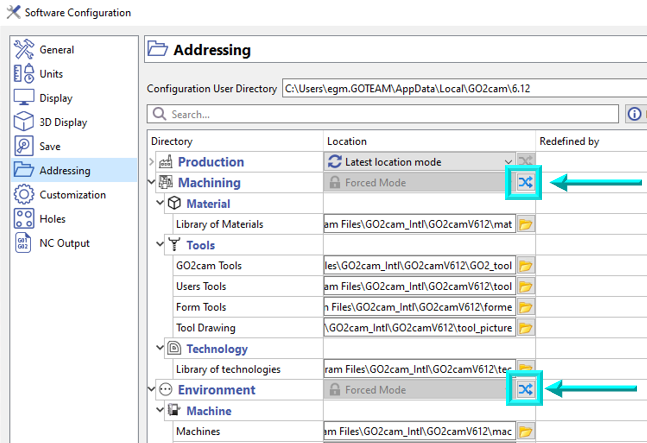

| One other consequence of the new structure of directories is the possibility to reassign addressing locations collectively. A new button is available for Machining and Environment categories. |  | |

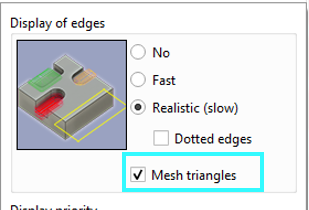

| OpenGL (3D Graphics) | The graphics engine is more performant. Open GL 4.0 is more visually pleasing and performant and is also better managed by recent graphics card. For customers with older configurations, openGL 2.0 is also better managed. | |

| Application Programming Interface (API) | ||

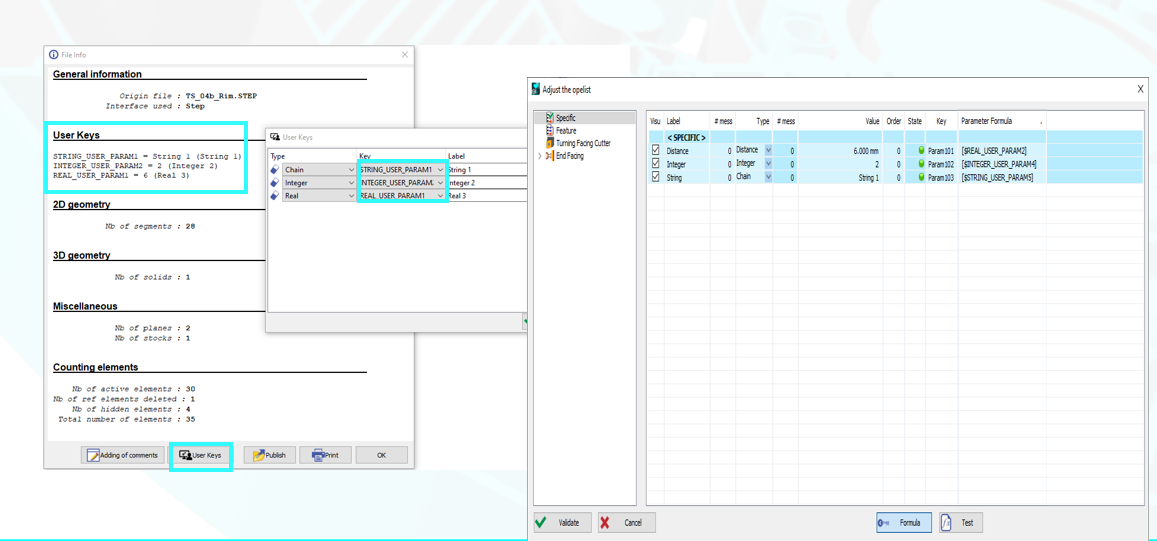

| User Parameters for Opelists, PPs, and JavaScript |

|  |

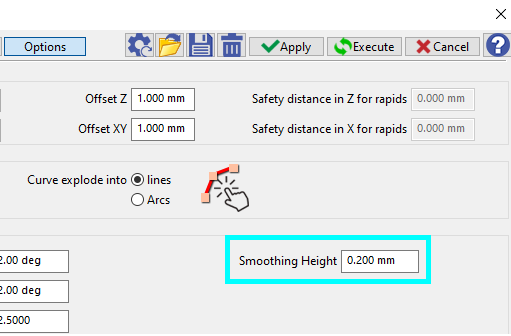

| 2 Axis Milling & Shape | ||

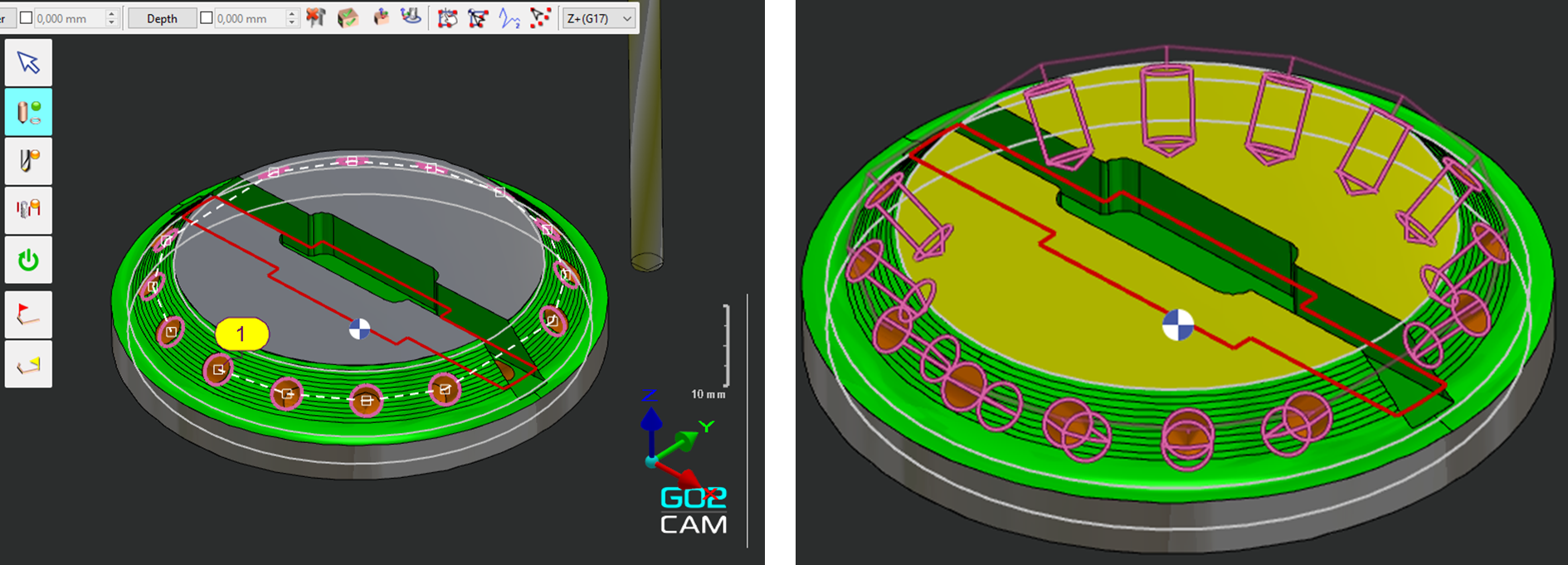

| Previously, circles were machined in the direction of the active machining plane (e.g., vertically in the example). Now, the circle’s normal direction is respected automatically, eliminating the need to create additional planes. |  | |

| 5 Axis Expert | ||

| ModuleWorks | Update to Version 2024.08 | |

| ModuleWorks | New Cycle for Machining on MESH elements. |  |

| Wire-Cut EDM | ||

| In the Dialog of Filters, we added a new type of entity ‘Threading point’. It enables to distinguish threading points from geometric points. |  | |

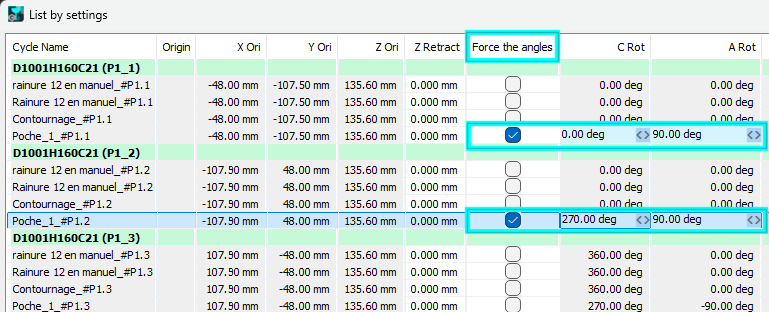

| Multiple-Parts Machining | ||

| List by Settings | We added a new option in the List by Settings that enables to choose among several possible combinations of angular positions. |  |

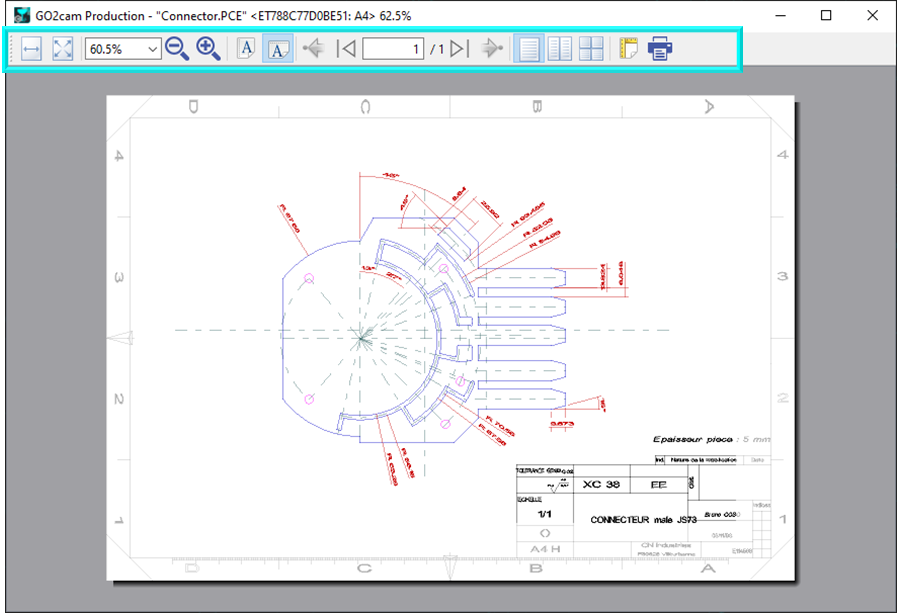

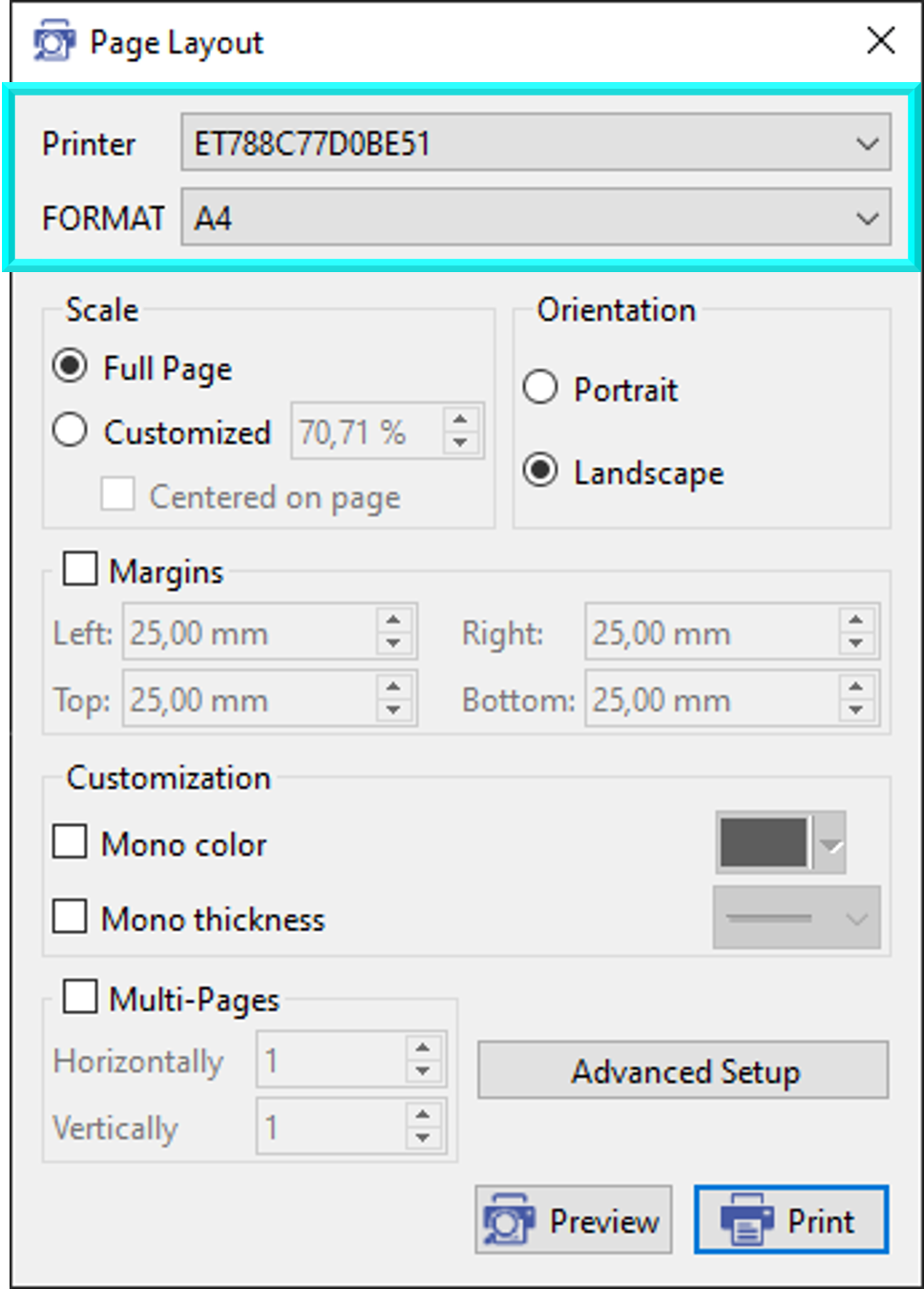

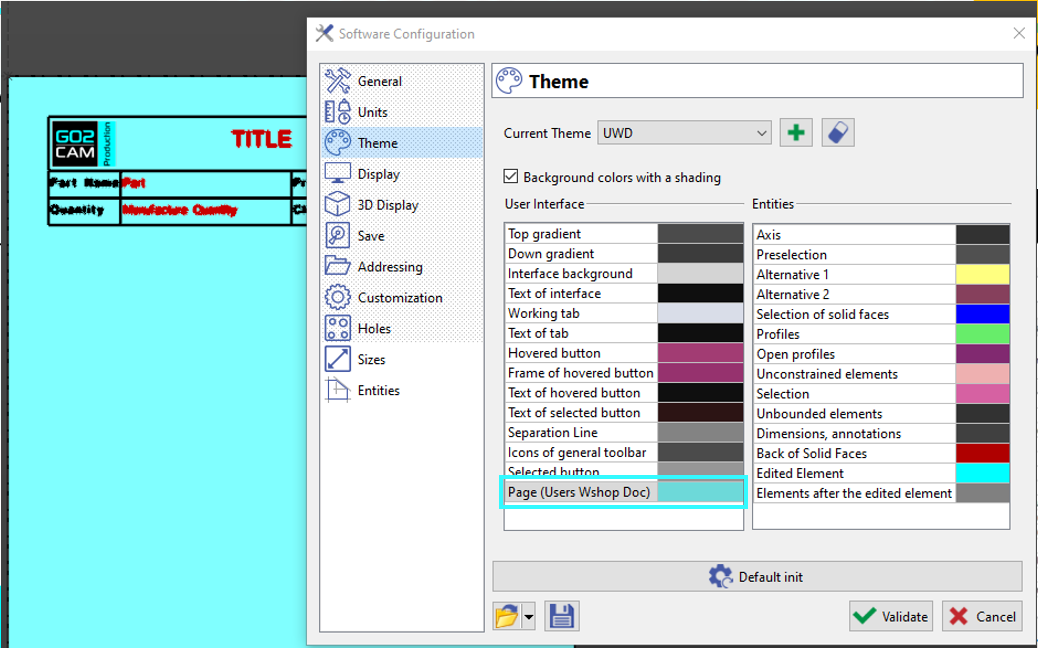

| User Workshop Document | ||

| New possibility to modify the background color of your page. It can be set in the Theme page of Tools > Options menu. |  | |